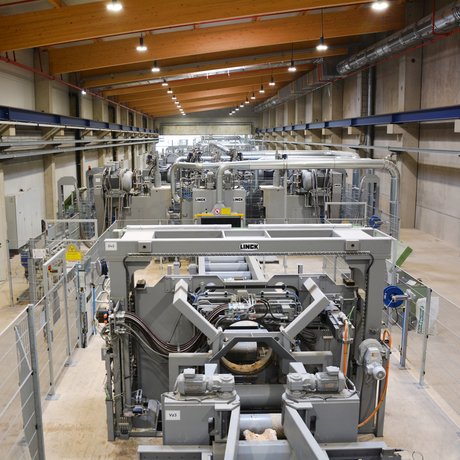

SGS major project: Mechanical assembly of the most modern sawmill in Europe

Project data

- Commissioner

- Rettenmeier

- Customer

- Rettenmeier

- Industry

- Wood & Sawmill industry

- Construction location

- Wilburgstetten, Germany

- Contruction period

- 14 months

- Contributors

- 90

Scope of delivery & service

Mechanical assembly of a complete sawmill:

- Sawmill infeed

- Sawing line

- Assessment

- Sorting

- Stacking

- Packaging for main and side cuts

- External infeed

- Re-sorting

- Batten handling

- Package handling

The individual construction areas

Our SGS team assembled the Linck sawmill infeed and sawing line in Wilburgstetten, Germany, the assessment of the 3 lines, the inclined multi-level sorter for the side cuts as well as the two single-board flat tray sorters for main cuts and re-sorting, stacking and packaging for main cuts and side cuts as well as re-sorting. The fully automatic batten handling system, the external infeed and the package handling system complete the scope of services.

The most modern sawmill

The new sawmill produces climate-friendly wood products of the highest standards, thereby combining resource efficiency with innovation and progress. The 62-hectare sawmill with a processing capacity of up to 1.3 million cubic metres produces wood products for timber construction and the DIY sector.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/f/7/csm_Montage-Rundholzplatz-Kundl-04_c91b44530a.jpg)