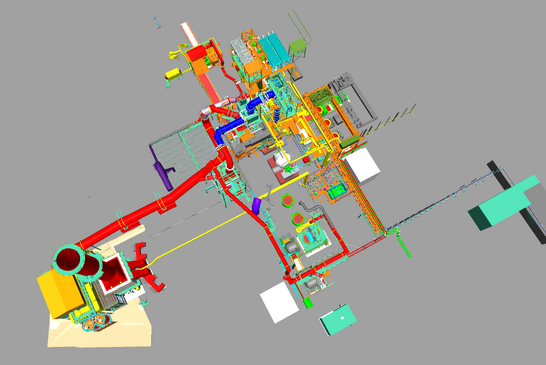

SGS assembled stainless steel converter incl. dedusting plant in Belgium

Our scope of work

The SGS team was responsible for upgrading the stainless steel converter AOD#1 including the dedusting system. The upgrade consisted of replacing the trunion ring, including the tipping station, and all modernisation work and it was completed during a shutdown of several weeks.

New installation of stainless steel converter AOD#2 incl. dedusting system.

A new plant was installed directly next to the stainless steel converter AOD#1. In addition, a new filter system for fume extraction was installed.

Challenges are there to be met.

In addition to the limited space available, there was a second component, time. The mechanical assembly of the plant had to be completed within a six-week shutdown.

The SGS team installed around 5,000 tonnes of plant components and steelwork as part of the upgrade and new construction.

Milestone reached: 14 tons assembled with millimeter precision by the #SGSteam in Belgium

A team of around 15 employees reached a milestone in the project in June 2023.

After four days of pre-assembly, the #SGSteam assembled the 14-ton section of the boiler piping in just 5 hours at the future location.

Some TIG weld seams in pre-assembly required around 12 hours of manpower.

After measuring and transport preparation by our team, the piece of pipe with a wall thickness of 20mm and 100% stress-free construction was assembled at a height of 60 meters using a 550 ton crane.

Project data

- Commissioner

- Primetals Technologies Austria als Konsortium Partner

- Customer

- Aperam Stainless Belgium

- Industry

- Metallurgy

- Construction location

- Genk, Belgium

- Contruction period

- 13 Months

- Contributors

- 160

- Specialties

- Constrained space as well as time pressure.

- Scope of delivery & service

-

Installation of a stainless steel converter incl. dedusting system.

About our customer Primetals Technologies Austria

Primetals Technologies Austria is one of the world's leading companies in the field of engineering, plant construction and lifecycle services for the metal industry. The company employs around 7,000 people worldwide. Primetals Technologies is composed of the predecessor companies Siemens VAI and Mitsubishi-Hitachi Metals Machinery. SGS is managing the contract with Primetals as a consortium partner.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/a/3/csm_SGS_montiert_eine_neue_Verchromungslinie_bei_thyssenkrupp_rasselstein_1_daa0f24f8e.png)